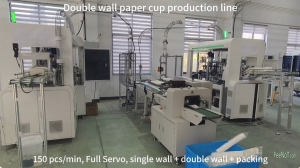

Machine à gobelets en papier à double paroi – Fabrication de vestes à manches ondulées, tous les servomoteurs, un équipement de formation de conteneurs en papier entièrement automatique, fabriquer et enrouler un manchon/une veste de deuxième couche autour des gobelets intérieurs en papier à paroi simple.

La vitesse de production est jusqu'à 150 PCS / Min, servomoteur complet de la meilleure qualité, écurie, vitesse, intelligent.

Faire des tasses en papier à double paroi anti-brûlure/isolation chaude pour café et thé.

Double Wall Paper Cup Machine 150s – Fabrication de vestes à manches ondulées

Pendant que l'eau chaude, le café et le thé remplissent des gobelets en papier à paroi simple, ils sont trop chauds pour être tenus à la main,

Parce que la chaleur va brûler le doigt de la main, à l'anti-brûlure, il faudrait donc faire un deuxième mur autour des gobelets en papier pour qu'ils soient chauds.

Machine à manchons de gobelets en papier à double paroi à ondulation servo complète, produire une tasse de papier peint ondulé, gobelets en papier à double paroi par rapport à la taille de la commande du client.

Modèle à double paroi: gobelets en papier creux, gobelets en papier ondulé/ondulé, gobelets en papier gaufré.

Comment fabriquer des gobelets en papier ondulé à double paroi?

Pour produire des gobelets en papier ondulé à double paroi, nécessitent que deux machines travaillent ensemble,

- 1St, 150Machine à gobelets en papier servo S, produire des gobelets en papier à simple paroi, tous servomoteurs, 150 PC / Minute.

- Ajouter un système de transfert intermédiaire, collecter et transférer les gobelets en papier à simple paroi vers une machine à manchons à double paroi,

- 2sd, machine de tasse de papier de double paroi d'ondulation , sceller le manchon de 2ème couche, et enroulez le manchon/la veste autour des coupelles à paroi simple, tous servomoteurs, 150 PC / Minute.

- 3rd, Machine d'emballage en papier, produire un sac à 3 côtés, emballer des gobelets en papier dans du plastique / sacs en papier.

- Ligne entière, entièrement automatique, grande vitesse, écurie, intelligent.

Spécifications de la machine à gobelets en papier à double paroi 150S avec servo complet

- Modèle: 150S DW16 servo complet,

- Vitesse: jusqu'à 150 PC / Minute,

- Tasse: 4~ 16 oz,

- Haut: 45~ 100 mm,

- Bas: 30~72mm,

- Hauteur: 30~ 135 mm,

- Matériel: 150~ 320gsm Film revêtu de papier, papier avec impression brillante/vernie,

- Colle à l'eau pour coller le manchon à double paroi et la coupelle intérieure..

- Colle à l'eau: (émulsion d'acétate de polyvinyle),

- Option: Colle thermofusible pour sceller les parois latérales, et ainsi de suite.

- Poids: 3000Kg,

- Machine:3200x1650x2100mm,

- Collectionneur: 900 x 700 x 2100 mm (Contre la taille de la tasse )

- Puissance totale: 30Kw (puissance de travail 8KW),

- Pouvoir: 380V 3 phases 50/60 HZ,

- Besoin d'air (pression:0.3~ 0,5 MPA, Sortir:300~ 500 L / M),

- Application: récipient de bol de tasses en papier à double paroi ondulée,

Processus de production de machine à gobelets en papier à double paroi ondulée:

- Alimenter le manchon à double paroi sur le ventilateur et l'entrée,

- Aspiration automatique du ventilateur du manchon, alimenter la machine,

- Sceller automatiquement le côté de la paroi du manchon, Scellement par ultrasons (option cuivre ), (ajouter un spray de colle thermofusible, option),

- Soulever la paroi du manchon jusqu'au moule principal, pli inférieur, colin (manchon creux à double paroi),

- Déposez et transférez la paroi du manchon sur la plaque de collage,

- Vaporisez un cercle de colle à eau (commande de servomoteur, faire tourner un cercle) à l'intérieur de la paroi du manchon,

- Le servo alimente la coupelle à paroi simple dans la paroi du manchon,

- Poussez le manchon dans l'espace du bord de la coupelle à paroi simple,

- Décharge, compter et collecter.

Servomoteurs

- Oblique sucer le servo en papier,

- Servo de joint à ultrasons,

- Servo de serrage d'aile de paroi de tasse,

- Éventail de tasses & servo de transfert mural,

- Servomage de flip mural de tasse,

- Serv,

- Servo grincer,

- 10 servo de plaque de séparation,

- 8 servo de plaque de séparation,

- Servo de décharge de tasse,

- Servo de pulvérisation de colle,

- Coupelle séparée servo,

Image:

machine-à-gobelets-en-papier-à-double-paroi-ondulation-150S-2

Machine de coupe en papier servo

Machine de coupe en papier servo