Medium Speed Paper Cup Machine ZBJ-X12 Video

Video link in youtube: Paper cup machine ZBJ-X12 medium speed

Medium Speed Paper Cup Machine ZBJ-X12 Brief Info:

# रफ़्तार: 60~85 pcs/minute

# कप का आकार: 2~12 ऑउंस

# सामग्री: 150~350 जीएसएम 1पीई & 2कागज पर,

# पीएलसी नियंत्रण, कैम खोलें + शाफ़्ट + गियर ड्राइव,

# Servo motor feed bottom, accurate and no waste,

# 11 sensors detect all steps, fault alarm & stop,

# Cup side welding: by Ultrasonic,

# कप तल तापन: by Air compressor Hot-Air,

# Quality electric parts(famous brand), Auto oil system

# कार्य -शक्ति: around 3.5KW

# शक्ति का स्रोत: 380वी 3-चरण 50/60 हर्ट्ज

# हवा की जरूरत है (दबाव:0.3~ 0.5mpa, उत्पादन:0.5 CBM/m)

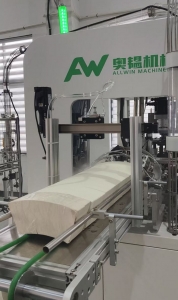

Medium Speed Paper Cup Machine ZBJ-X12 Picture

Medium Speed Paper Cup Machine ZBJ-X12 Specification :

| नमूना | ZBJ-X 12 Heater | ZBJ-X 12 अल्ट्रासोनिक | ZBJ-X22 अल्ट्रासोनिक |

| कागज का आकार: | 40ml ~ 12oz | 2 ~ 12 आउंस | 8~22 आउंस |

| शीर्ष: 45~95mm

तल: 35~78mm ऊंचाई: 40~115mm |

शीर्ष: 60~95मिमी

तल: 45~78मिमी ऊंचाई: 60~170mm |

||

| मूल्याँकन की गति: | 60~75 PCS/minute | 50~70 PCS/minute | |

| कच्चा माल: | One side PE Paper | One-side or two साइड पीई फिल्म लेपित कागज | |

| उपयुक्त कागज भार: | 140~250gsm | 180~350जीएसएम | |

| शक्ति का स्रोत: | (बेहतर उपयोग 380V 3-चरण) * if User power different? Please INFO US IN ADVANCE. | ||

| कुल शक्ति: | 6किलोवाट | 6किलोवाट | |

| कार्य शक्ति: | 3.5 किलोवाट | 3.5 किलोवाट | |

| कुल भार: | Gw/nw: 2500/2350किलोभास | Gw/nw: 2700/2500किलोभास | |

| पैक का आकार (L*w*h) | 2750 एक्स 1240 एक्स 1800 मिमी | 2800x1300x1900 | |

| वर्किंग एयर सोर्स: | हवा का दबाव:0.4एमपीए; हवा के बाहर:0.6एम/मिनट, (User should BUY Air Compressor ) | ||

| कप साइड वेल्डिंग: | Pre-heating + Heater | अल्ट्रासोनिक | |

| कप बॉटम हीटिंग: | Heater (40ml~100ml) | गरम हवा (Need Air compressor supply air) | |

| गरम हवा (100ml~300ml) | |||

| कप बॉटम नूरलिंग: | Heater | हीटर (यदि एकल पीई लेपित कागज का उपयोग करें) | |

| कूल डिवाइस (circle water), डबल पे लेपित पेपर के लिए | |||

| हम बिना किसी पूर्व सूचना के विशिष्टताओं में परिवर्तन करने का अधिकार सुरक्षित रखते हैं. | |||

Medium Speed Paper Cup Machine ZBJ-X12 More Details :

1, गियर्स & अक्ष नियंत्रण आंदोलन, दो इंडेक्स गियर बॉक्स, more efficient & accurate.

2, गुणवत्ता 125# index gear box + 80# index gear box to keep machine stable,

3, एचएमआई & PLC Program computer control, आसान संचालन, fault auto-stop and easy solution.

4, All procedure sensor detect (11-sensor control all step), Less wastage & fault, Reliable.

5, Servo motor control bottom feed, one cup body one bottom punch, precession, no wastage.

6, Self lubrication (Automatic Oil Lubrication for machine moving part), दीर्घ जीवन काल.

7, Import electric Elements, Superior Bearing & Quality material, more durable and reliable.

8, Working power only 3.5KW, save electric power cost.

9, One worker can run 2sets machine (machine assemble cup stock), श्रम लागत बचाएं.

सर्वो पेपर कप मशीन

सर्वो पेपर कप मशीन