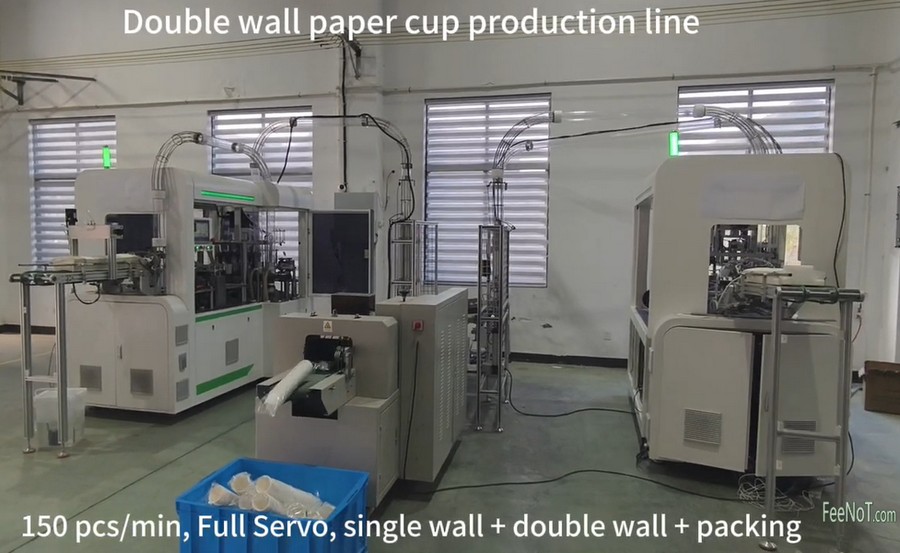

Cara membuat paper cup riak dan double wall? Lini mesin produksi cangkir kertas riak dinding ganda 150S, untuk menghasilkan dua lapisan anti panas, hot insulation coffee ripple double wall paper cups.

Require, single wall paper cup forming machine + double wall paper cup sleeve glue machine.

Cara membuat gelas kertas dinding ganda riak?

Cara membuat gelas kertas dinding ganda riak?

Untuk menghasilkan cangkir kertas dinding ganda yang beriak, require machines working together,

150s semua mesin cangkir kertas dinding tunggal servo + 150S DW16 semua mesin lengan cangkir kertas dinding ganda servo + mesin pengepakan

150s semua mesin cangkir kertas dinding tunggal servo + 150S DW16 semua mesin lengan cangkir kertas dinding ganda servo + mesin pengepakan

- 1st, 150Mesin cangkir kertas servo S, menghasilkan cangkir kertas dinding tunggal, semua digerakkan oleh servo, 150 PC/menit.

- 2dan, Tambahkan sistem transfer tengah, kumpulkan dan pindahkan cangkir kertas dinding tunggal ke mesin selongsong dinding ganda,

- 3rd, mesin cangkir kertas dinding ganda riak , segel selongsong lapisan ke-2, dan bungkus lengan/jaket di sekitar cangkir dinding tunggal, semua digerakkan oleh servo, 150 PC/menit.

- 4th, mesin pengepakan cangkir kertas, menghasilkan tas 3 sisi, mengemas gelas kertas ke dalam plastik / kantong kertas.

- Seluruh baris, sepenuhnya otomatis, kecepatan tinggi, stabil, cerdas.

Info of double wall paper cup production machine

Fully automatic, all servo, Mesin lengan cangkir kertas dinding ganda kopi 8oz sekali pakai, menghasilkan cangkir kertas dinding riak, cangkir kertas dinding ganda terhadap ukuran pelanggan.

Sementara air panas kopi teh ke dalam satu cangkir kertas dinding, terlalu panas untuk dipegang dengan tangan, panasnya akan melepuh jari tangan, untuk anti panas, buat dinding kedua di sekeliling cangkir kertas agar tidak panas.

Gaya dinding ganda: Lengan berongga: cangkir kertas dinding ganda,

Lengan lurus: cangkir kertas riak/bergelombang, cangkir kertas timbul, dan sebagainya.

Specification of double wall paper cup production machine

- Model: 150S DW16,

- Kecepatan: hingga 150 PC/menit,

- Ukuran cangkir: 4~ 16oz,

- Atas: 45~ 100 mm,

- Dasar: 30~72mm,

- Tinggi: 30~ 135 mm,

- Bahan: 150~ Kertas berlapis film 320gsm, kertas dengan cetakan glossy/pernis,

- Lem air menempelkan selongsong dinding ganda dan cangkir bagian dalam.

- Lem Air: (emulsi polivinil asetat),

- Pilihan: Lem panas meleleh untuk menyegel dinding samping, dan sebagainya.

- Berat: 3000Kg,

- Mesin:3200x1650x2100mm,

- Pengumpul: 900 X 700 x 2100mm (terhadap ukuran cangkir )

- Kekuatan total: 30KW (daya kerja 8KW),

- Kekuatan: 380V 3-fase 50/60 Hz,

- Butuh udara (tekanan:0.3~ 0,5mpa, Keluaran:300~ 500 l/m),

- Aplikasi: wadah mangkuk cangkir kertas dinding ganda riak,

Gambar:

Lini mesin produksi cangkir kertas riak dinding ganda 150S

Mesin gelas kertas servo

Mesin gelas kertas servo