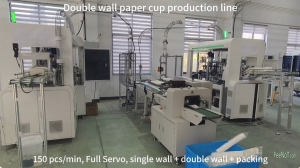

Mesin Piala Kertas Dinding Ganda – Pembuatan jaket lengan riak, all servo drive, a fully automatic paper container forming equipment, make and wrap a second layer sleeve/jacket around inner single wall paper cups.

Kecepatan produksi hingga 150 pcs/mnt, best quality full servo drive, stabil, kecepatan, smart.

Making anti scalding/hot insulation coffee tea ripple double wall paper cups.

Double Wall Paper Cup Machine 150s – Pembuatan jaket lengan riak

While hot water coffee tea fill into single wall paper cups, they are too hot to hold by hand,

Because the heat will scald the hand finger, untuk anti panas, so should make a second wall around paper cups to provent hot.

Full servo ripple double wall paper cup sleeve machine, menghasilkan cangkir kertas dinding riak, double wall paper cups against customer order size.

Gaya dinding ganda: hollow paper cups, cangkir kertas riak/bergelombang, cangkir kertas timbul.

Cara membuat gelas kertas dinding ganda riak?

Untuk menghasilkan cangkir kertas dinding ganda yang beriak, memerlukan dua mesin yang bekerja bersama,

- 1st, 150Mesin cangkir kertas servo S, menghasilkan cangkir kertas dinding tunggal, semua digerakkan oleh servo, 150 PC/menit.

- Tambahkan sistem transfer tengah, kumpulkan dan pindahkan cangkir kertas dinding tunggal ke mesin selongsong dinding ganda,

- 2dan, mesin cangkir kertas dinding ganda riak , segel selongsong lapisan ke-2, dan bungkus lengan/jaket di sekitar cangkir dinding tunggal, semua digerakkan oleh servo, 150 PC/menit.

- 3rd, mesin pengepakan cangkir kertas, menghasilkan tas 3 sisi, mengemas gelas kertas ke dalam plastik / kantong kertas.

- Seluruh baris, sepenuhnya otomatis, kecepatan tinggi, stabil, cerdas.

Specification of Double Wall Paper Cup Machine 150S Full Servo

- Model: 150S DW16 Full servo,

- Kecepatan: hingga 150 PC/menit,

- Ukuran cangkir: 4~ 16oz,

- Atas: 45~ 100 mm,

- Dasar: 30~72mm,

- Tinggi: 30~ 135 mm,

- Bahan: 150~ Kertas berlapis film 320gsm, kertas dengan cetakan glossy/pernis,

- Lem air menempelkan selongsong dinding ganda dan cangkir bagian dalam.

- Lem Air: (emulsi polivinil asetat),

- Pilihan: Lem panas meleleh untuk menyegel dinding samping, dan sebagainya.

- Berat: 3000Kg,

- Mesin:3200x1650x2100mm,

- Pengumpul: 900 X 700 x 2100mm (terhadap ukuran cangkir )

- Kekuatan total: 30KW (daya kerja 8KW),

- Kekuatan: 380V 3-fase 50/60 Hz,

- Butuh udara (tekanan:0.3~ 0,5mpa, Keluaran:300~ 500 l/m),

- Aplikasi: wadah mangkuk cangkir kertas dinding ganda riak,

Ripple double wall paper cup machine production process:

- Feed double wall sleeve on the fan seender and entry,

- Auto suck the sleeve fan, feed to machine,

- Auto seal the sleeve wall side, Ultrasonic sealing (opsi tembaga ), (add Hot melt glue spray, pilihan),

- Lift sleeve wall to main mold, lipatan bawah, Knurling (selongsong cangkir dinding ganda berongga),

- Drop and transfer sleeve wall to stick-plate,

- Spray a circle water glue (kendali motor servo, memutar lingkaran) di dalam dinding lengan,

- Servo feed single wall cup into sleeve wall,

- Push the sleeve into single wall cup rim space,

- Discharge, menghitung dan mengumpulkan.

Servos

- Servo kertas hisap miring,

- Ultrasonic seal servo,

- Cup wall wing clamp servo,

- Penggemar piala & wall transfer servo,

- Servo flip dinding cangkir,

- Servo pengangkat dinding cangkir,

- Servo Knurling,

- 10 divide plate servo,

- 8 divide plate servo,

- Cup discharge servo,

- Glue spray servo,

- Cup separate servo,

Gambar:

ripple-double-wall-paper-cup-machine-150S-2

Mesin gelas kertas servo

Mesin gelas kertas servo