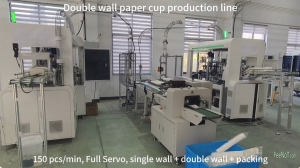

Macchina per bicchieri di carta a doppia parete 150S Full Servo, un'attrezzatura per la formatura di contenitori di carta completamente automatica, realizzare e avvolgere una manica/giacca di secondo strato attorno ai bicchieri di carta interni a parete singola.

La velocità di produzione spetta a 150 PCS/min, servoazionamento completo della migliore qualità, stabile, velocità, accorto.

Realizza bicchieri di carta a doppia parete con ondulazione per tè e caffè antiscottatura/isolamento caldo.

Macchina per bicchieri di carta a doppia parete 150S Full Servo

Mentre l'acqua calda, il caffè e il tè vengono riempiti in bicchieri di carta a parete singola, sono troppo caldi per tenerli in mano,

Perché il calore scotterà il dito della mano, all'antiscottatura, quindi dovresti creare un secondo muro attorno ai bicchieri di carta per farli scaldare.

Macchina per maniche a tazza di carta a doppia parete completamente servoondulata, produrre una tazza di carta da parati ondulata, bicchieri di carta a doppia parete rispetto alle dimensioni dell'ordine del cliente.

Stile a doppia parete: bicchieri di carta vuoti, bicchieri di carta ondulata/ondulata, bicchieri di carta goffrata.

Come realizzare bicchieri di carta ondulati a doppia parete?

Per produrre bicchieri di carta ondulati a doppia parete, richiedono che due macchine lavorino insieme,

- 1st, 150Macchina per bicchieri di carta S servo, produrre bicchieri di carta a parete singola, tutto servocomandato, 150 pz/minuto.

- Aggiungi un sistema di trasferimento intermedio, raccogliere e trasferire i bicchieri di carta a parete singola nella macchina per maniche a doppia parete,

- 2nd, macchina per bicchieri di carta a doppia parete ondulata , sigillare la manica del 2° strato, e avvolgere la manica/giacca attorno alle coppe a parete singola, tutto servocomandato, 150 pz/minuto.

- 3rd, macchina da imballaggio di carta, produrre una borsa a 3 lati, confezionare bicchieri di carta in plastica / sacchetti di carta.

- Tutta la linea, Completamente automatico, ad alta velocità, stabile, intelligente.

Specifiche della macchina per bicchieri di carta a doppia parete 150S Full Servo

- Modello: 150S DW16 Servo completo,

- Velocità: fino a 150 pz/minuto,

- Taglie di tazza: 4~ 16oz,

- Superiore: 45~ 100 mm,

- Metter il fondo a: 30~72 mm,

- Altezza: 30~ 135 mm,

- Materiale: 150~ Carta patinata con pellicola da 320 g/m², carta con stampa lucida/verniciata,

- La colla ad acqua attacca il manicotto a doppia parete e la tazza interna.

- Colla ad acqua: (emulsione di acetato di polivinile),

- Opzione: Colla a caldo per la sigillatura delle pareti laterali, e così via.

- Peso: 3000KG,

- Macchina:3200x1650x2100 mm,

- Collettore: 900 X 700 X 2100mm (contro la taglia di coppa )

- Potenza totale: 30KW (potenza di lavoro 8KW),

- Energia: 380V 3-Fase 50/60 Hz,

- Hai bisogno di aria (pressione:0.3~ 0,5MPA, Produzione:300~ 500 l/m),

- Applicazione: Contenitore per bicchieri di carta a doppia parete ondulato,

Processo di produzione della macchina per bicchieri di carta a doppia parete ondulata:

- Alimentare il manicotto a doppia parete sulla ventola e sull'ingresso,

- Aspira automaticamente la ventola della manica, alimentare alla macchina,

- Sigilla automaticamente il lato della parete del manicotto, Sigillatura ad ultrasuoni (opzione rame ), (aggiungere colla spray a caldo, opzione),

- Sollevare la parete del manicotto verso lo stampo principale, piega inferiore, Knurling (manicotto della tazza cavo a doppia parete),

- Rilasciare e trasferire la parete del manicotto sulla piastra adesiva,

- Spruzzare un cerchio di colla ad acqua (controllo del servomotore, ruotare un cerchio) all'interno della parete del manicotto,

- Servoalimentare la tazza a parete singola nella parete del manicotto,

- Spingere il manicotto nello spazio sul bordo della tazza a parete singola,

- Scarico, contare e raccogliere.

Servi

- Servo di carta succhia obliqua,

- Servo tenuta ad ultrasuoni,

- Servo morsetto ad ala da parete della tazza,

- Tifoso della Coppa & servo di trasferimento a parete,

- Servo per il ribaltamento della parete della tazza,

- Servo sollevamento parete tazza,

- Servo cigolio,

- 10 servo della piastra divisa,

- 8 servo della piastra divisa,

- Servo scarico tazza,

- Servo colla spray,

- Servo separato per tazza,

Immagine:

Macchina per bicchieri di carta a doppia parete 150S Full Servo Fast & Stabile

Macchina per bicchieri di carta a doppia parete 150S Full Servo: Veloce & Stabile

Servo Paper Cupt Machine

Servo Paper Cupt Machine