셀프 워터 스프레이 서보 페이퍼 컵 제작 & 포장 기계, 일회용 종이 컵 만들기, 속도를 높이십시오 150 PC/분,

완전한 서보 구동, 셀프 워터 스프레이 시스템으로, 지능적인, 완전 자동, 고품질, more stable and reliable, less maintenance cost.

Self water spray system, Reduce labor intensity, save the labor cost,

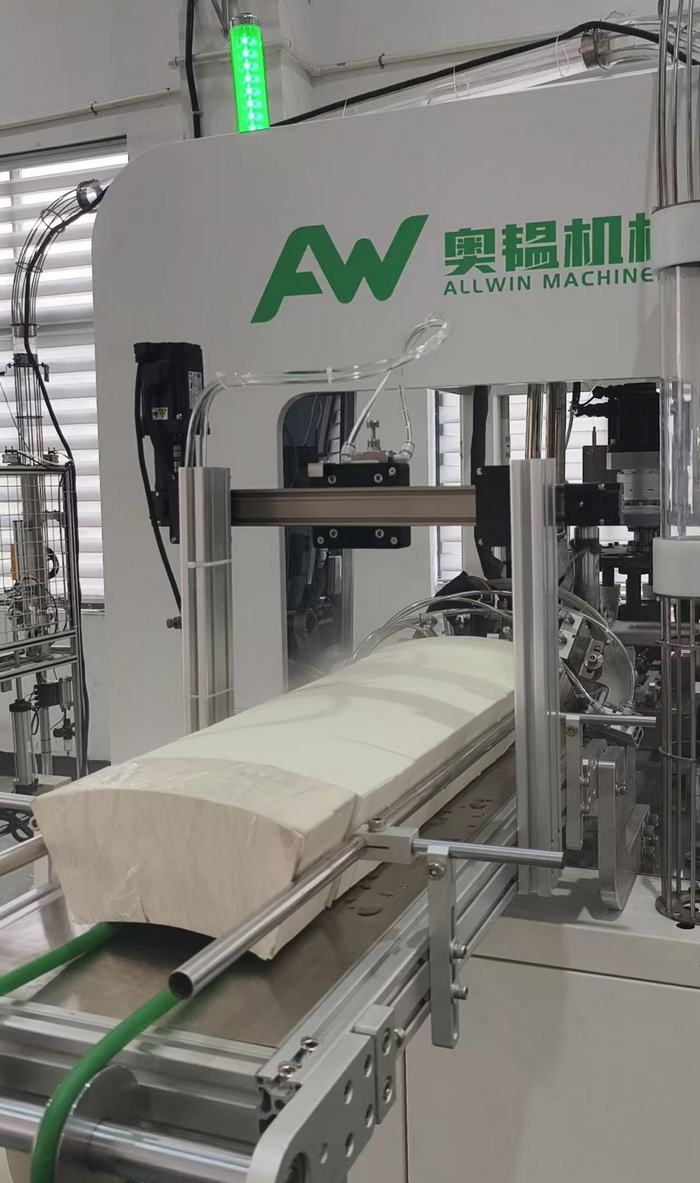

Cup packaging machine, automatic packing paper cups into plastic bag, 종이 봉지, 비용 절감.

셀프 워터 스프레이 서보 페이퍼 컵 제작 & 포장 기계

150S 풀 서보 종이컵 기계는 서보 모터를 통해 각 움직이는 부분을 구동하여 성형을 실현합니다., 컬링, 바닥 펀칭 및 기타 종이컵 공정.

서보 모터의 고정밀 제어로 종이컵 생산 공정이 더욱 안정적이고 정밀해집니다..

컵 포장기와 온라인으로 연결하는 동안, 완전 자동, 인건비를 절약하고.

애플리케이션: 뜨거운 음료 커피 차 우유 종이컵, 차가운 음료수 코카콜라 주스 종이컵, 아이스크림 종이 컵, 감자 칩 컵, 및 기타 식품 패키지 솔루션.

기존의 부피가 크고 복잡한 컵 제조 장비와 비교했을 때 (장축, 기어, 캠, 쇠사슬, 모래밭).

부품이 부러진 경우, 사용자는 모든 구조 기어 캠을 이동해야합니다, 수리 또는 교체가 어렵습니다, 따라서 기계 정지를 유발하십시오.

Paper cup machine full servo 150s Main features:

# 11세트 anascence 서보 기구 + 11세트 쇼포 감속기

# 10PCS 합금 메인 몰드 + 8PC 컬링 곰팡이

1, 높은 정밀도: 서보 모터는 정확한 위치 제어 및 속도 제어를 달성 할 수 있습니다., 따라서 종이 컵의 형성 정확도를 보장합니다.

2, 고효율: 서보 모터의 빠른 응답과 고속은 종이 컵의 생산 효율을 크게 향상시킵니다..

3, 높은 수준의 자동화: 고급 제어 시스템이 장착되어 있습니다, 종이 수유에서 종이 컵 형성에 이르기까지 완전히 자동화 된 생산을 달성 할 수 있습니다..

4, 최고의 안정성: 서보 모터의 안정성과 신뢰성이 높습니다, 장비의 실패율 및 유지 보수 비용을 줄일 수 있습니다..

5, 기계는 효율성을 향상시키기 위해 모듈 식 설계를 채택합니다, 유지 보수 및 업그레이드를 용이하게합니다, 표준화 및 호환성을 촉진합니다;

6, 그룹화 된 서보 모션 제어 시스템은 정확도를 보장합니다, 기계 작동의 속도와 안정성;

7, 지능형 중앙 석유 공급 윤활 시스템은 주기적 석유 교체 비용을 절약합니다., 석유 오염의 문제를 줄입니다, 에너지를 절약하고 환경 친화적입니다;

8, 10-인치 인간-기계 상호 작용 인터페이스는 기계를 편리하고 효율적으로 작동합니다., 감지 시스템이 장착 될 수 있습니다.

셀프 워터 스프레이 서보 페이퍼 컵 제작 & packaging machine Advantage:

- 10PC 품질 서보 모터 시스템은 기존의 복잡한 메커니즘 전송을 대체합니다.,

- 오래된 부피가 큰 긴 샤프트 캠 그어 쉬운 마모, 고장난,

- 1, 비스듬한 종이 서보,

- 2, 컵 벽 랩 & 초음파 씰 서보,

- 3, 팬 블랭크 & 컵 벽 전송 서보,

- 4, 컵 벽 플립 서보,

- 5, 컵 벽 리프트 서보,

- 6, 하단 롤 피드 서보,

- 7, 하단 디스크 푸시 업 서보,

- 8, 삐걱 거리는 서보 (하단 펀치, 난방, knurling, 상단 컬링),

- 9, 10 인덱스 메인 몰드 플레이트 서보,

- 10, 8 인덱스 컬링 금형 플레이트 서보.

- 서보+ECAM+PLC+HMI, 효율적인, 지능적인, 안정적인, 믿을 수 있는,

- 전체 서보, 정확성, 안정적인, 믿을 수 있는, 간단한 작동, 더 적은 & 쉬운 유지 보수.

- 10PC 품질의 Ally Cup Mold, 각도 36 도,

- 8PC 컬링 곰팡이 (두 번 컬링), 각도 45 도,

- 38MM 두꺼운 전체 철강 보드 구조 기반, 안정적인 & 믿을 수 있는,

- 팬 벽 블랭크 피더 1 미터 (고속, 한 번 더 빈 공간을 공급하십시오)

- 상단 림 두 번 컬링, 컵 강력하고 최고의 전망,

- 컵 벽 용접: 초음파 + 세라믹 뜨거운 공기,

- 바닥 난방: 세라믹 뜨거운 공기 (2PC 4.4kW),

Specification of Paper cup machine full servo 150s:

- 모델: 150풀 서비스,

- 속도: 150 PC/분 (9000 컵/시간),

- 컵 크기: 3~ 16oz,

- 맨 위: 45~ 100 mm,

- 맨 아래: 38~ 70 mm,

- 키: 45~ 135 mm,

- 재료: 150~ 320 GSM 1PE & 2종이에,

- 무게: 3350kg,

- 기계:3200x1650x1900mm,

- 수집기: 1100 엑스 1100 x 2100mm (컵 크기에 대해 ),

- 작동력 10kW, 총 전력: 35KW,

- 힘: 380v 3 상 50/60 HZ,

- 공기가 필요합니다 (압력:0.3~ 0.5mpa, 산출:300~ 500 l/m),

- 애플리케이션: 더운 (커피 차) 추운 (Cola Juic Icecream) 종이 컵,

셀프 워터 스프레이 서보 페이퍼 컵 제작 & 포장 기계

서보 페이퍼 컵 기계

서보 페이퍼 컵 기계