Rippel paper calicem machine – Duplex murum calicem machinam faciens, Celeritas usque ad 150 PCs / min, Omnes servo coegi, Make and wrap a jacket sleeve around inner single wall paper cups.

Produce 3~16oz, anti scalding / hot insulation coffee tea ripple double wall paper cups, embossing corrugated paper cups.

Rippel paper calicem machine – Duplex murum calicem machinam faciens

Dum calida aqua capulus tea in unum pariete charta pocula, it is too hot to hold by hand,

Et calor et scaldum manum digito, ad anti-scalding,

so that we make a second wall around paper cups to provent hot.

Plena servo laniatus duplici muro charta poculum sleeve machina, producit murum chartam laniatus poculum, duplicem murum chartae scyphi contra mos ordinis magnitudine.

Duplex murus style: cava charta scyphi, laniatus / CONRUGIS charta scyphi, cyathos caelatum charta.

Quomodo murum charta duplici reddere cyathos?

Ad murum charta duplici cacumina, machinis opus unum requirere duo,

- 1st*, 150S servo charta poculum machina, unum murum chartae scyphi, Omnes servo pulsus, 150 PCs / Minutum.

- Addere medium translationis ratio, s,

- 2nd *, laniatus duplici muro charta poculum machinae , signantes 2 accumsan sleeve, et involvunt sleeve / iaccam circa unum murum scyphi, Omnes servo pulsus, 150 PCs / Minutum.

- 3rd *, charta poculum sarcina machina, producendum III-parte sacculi, packaging charta scyphi in plastic / charta sacculos.

- Tota linea, plene automatic, summus, stabulum, intelligens.

Specification de Rippica paper calicem apparatus 150s

- Exemplar: 150S D D D D D D D D D,

- Celeritate: ad 150 PCs / Minutum,

- Cup: 4~ 16oz,

- Top: 45~ C mm,

- Imo: 30~ LXXII mm,

- Altitudo: 30~ CXXXV mm,

- Materia: 150~ 320gsm film iactaret charta, Charta cum nitidum nitidum / Varnish print,

- Aqua glutine lignum duplex murus sleeve et interiore poculum.

- Aquam gluten: (Polyvinyl Acetate EMULSIO),

- Optio: Calidum Melt gluten latus murum signantes, et sic in.

- Pondus: 3000Kg,

- Machina:3200x1650x2100mm,

- Collector: 900 X 700 x 2100mm (in calicem magnitudine )

- Summa: 30KW (Opus Power 8KW),

- Potentia: 380V III-phase 50/60 HZ,

- Opus caeli (pressura:0.3~ 0.5MPA, Output:300~ D l / m),

- Applicatio: Rippel Duplex Wall Paper Campy Crater continens,

Ripple duplex murum charta poculum apparatus productionis processus:

- Pasce duplici muro manica in ventilabrum videntis et viscus,

- Auto sugere sleeve fan, pascat ut machina,

- Auto parietem manica latus, Ultrasonic signatio (aera ), (addere Hot conflandum gluten imbre, optio),

- Erige sleeve murum ad principale fingunt, imo complicare, SCRUTOR (Duplex Wall Cuple Sleeve),

- Gutta et transferre sleeve murum ad baculum-laminam,

- Circulus aquae gluten imbre (Motor Imperium, Rotate circulus) Intus sleeve Wall,

- Servo calix parietis unius murus in manica,

- Ventilabis manica in uno pariete calicem ora spatium,

- Dimittite, comitem et orationem.

Servos

- Obliquus chartam lactis servo,

- Sigillum ultrasonic servo,

- Calicem murum cornu Fibulae servo,

- Poculum fan & muro translatio servo,

- Calicem murum flip servo,

- Calicem murum levare servo,

- Knurling servo,

- 10 divide laminam servo,

- 8 divide laminam servo,

- Calicem missionem servo,

- Gluten imbre servo,

- Poculum separatum servo,

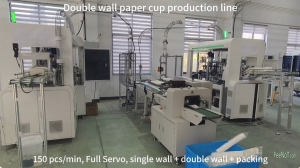

Pictura:

Ripple paper scyphus machina duplex murum calicem faciens machina

Rippel paper calicem machine – Duplex murum calicem machinam faciens

Servo Charta Cup Machina

Servo Charta Cup Machina