Uma máquina servo de produção de copo de papel com spray de água automático 150s é uma tecnologia avançada, dispositivo automatizado para fazer copos de papel, featuring an internal spray system for cup fan side water-spray (instead of traditional manual spray water ),

often combined with servo motors for precision, alta velocidade 150 cups/min,

and online packaging, leading to eco-friendlier, smoother, and more efficient cup production with lower costs.

Máquina servo de produção de copo de papel com spray de água automático 150s

Self water spray sytem (auto spray water system), help customer save the labor, avoid user forget to spray water.

The core function of the automatic water sprayer is to soften the paper cup paper through precise water spraying, assisting with bending, formação, and bonding, preventing cracking and creating a smoother curl.

Water spray is important to make cups curling rim good (avoid cup top rim burst / split ), or even affect the cup side wall sealing. Factor is paper character.

Some paper need spray more water (even spray water 2 hours before feed to machine), some less.

Set the spray water time and speed against: machine speed, espessura do papel, paper character, circumstance(climate).

Parts includes:

Servo motor, Linear guide/shaft, Water spray, Water pump, Water tank (20~30L), Air control system (in machine plc), PLC control system (in machine plc).

Máquina servo de produção de copo de papel com spray de água automático 150s

150S Full Servo Paper Cup Machine dirige cada parte em movimento através de um motor servo para realizar a formação, ondulação, perfuração inferior e outros processos de copos de papel.

O controle de alta precisão do motor servo torna o processo de produção de copos de papel mais estáveis e precisos.

Enquanto se conecta com a máquina de embalagem de copos online, Totalmente automático, e salvar o custo do Laber.

Aplicativo: Hot Drinks Coffee Tea Milk Papel, bebida fria coca cola suco de papel copos, xícaras de papel de sorvete, Fries chips xícaras, e outra solução de pacote de alimentos.

Quando comparado com o antigo equipamento de copo volumoso complexo (eixo longo, engrenagens, cames, correntes, links).

Se alguma peça quebrada, O usuário deve mover toda a estrutura de engrenagem de estrutura, difícil de reparar ou substituir, Assim, causa a parada da máquina.

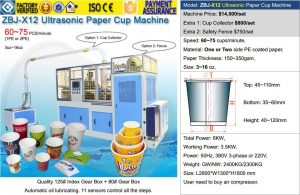

Especificação de todas as máquinas servo de copo de papel 150s:

- 10PCS Anascença Servo + 10PCS Shimpo REDUTOR

- 10Molo de liga PCS molde principal + 8PCS molde de curling

- Modelo: 150S all servo,

- Velocidade: até 150 PCs/min (9000 Copas/hora),

- Tamanho do copo: 3~ 16oz,

- Principal: 45~ 100 mm,

- Fundo: 38~ 70 mm,

- Altura: 45~ 135 mm,

- Material: 150~ 320 GSM 1PE & 2No papel,

- Peso: 3350KG,

- Máquina:3200x1650x1900mm,

- Coletor: 1100 x 1100 x 2100mm (contra o tamanho do copo ),

- Poder de trabalho 10kW, Poder total: 35KW,

- Poder: 380V 3-fase 50/60 Hz,

- Precisa de ar (pressão:0.3~ 0,5mpa, Saída:300~ 500 l/m),

- Aplicativo: quente (chá de café) frio (Cola JUIC Icecream) Copo de papel,

Máquina servo de produção de copo de papel com spray de água automático 150s

Máquina servo de produção de copo de papel com spray de água automático 150s is an advanced, dispositivo automatizado para fazer copos de papel, featuring an internal spray system for cup fan side water-spray (instead of traditional manual spray water ),

often combined with servo motors for precision, alta velocidade 150 cups/min,

and online packaging, leading to eco-friendlier, smoother, and more efficient cup production with lower costs.

Máquina servo de produção de copo de papel com spray de água automático 150s

Self water spray sytem (auto spray water system), help customer save the labor, avoid user forget to spray water.

The core function of the automatic water sprayer is to soften the paper cup paper through precise water spraying, assisting with bending, formação, and bonding, preventing cracking and creating a smoother curl.

Water spray is important to make cups curling rim good (avoid cup top rim burst / split ), or even affect the cup side wall sealing. Factor is paper character.

Some paper need spray more water (even spray water 2 hours before feed to machine), some less.

Set the spray water time and speed against: machine speed, espessura do papel, paper character, circumstance(climate).

Parts includes:

Servo motor, Linear guide/shaft, Water spray, Water pump, Water tank (20~30L), Air control system (in machine plc), PLC control system (in machine plc).

Máquina servo de produção de copo de papel com spray de água automático 150s

150S Full Servo Paper Cup Machine dirige cada parte em movimento através de um motor servo para realizar a formação, ondulação, perfuração inferior e outros processos de copos de papel.

O controle de alta precisão do motor servo torna o processo de produção de copos de papel mais estáveis e precisos.

Enquanto se conecta com a máquina de embalagem de copos online, Totalmente automático, e salvar o custo do Laber.

Aplicativo: Hot Drinks Coffee Tea Milk Papel, bebida fria coca cola suco de papel copos, xícaras de papel de sorvete, Fries chips xícaras, e outra solução de pacote de alimentos.

Quando comparado com o antigo equipamento de copo volumoso complexo (eixo longo, engrenagens, cames, correntes, links).

Se alguma peça quebrada, O usuário deve mover toda a estrutura de engrenagem de estrutura, difícil de reparar ou substituir, Assim, causa a parada da máquina.

Especificação de todas as máquinas servo de copo de papel 150s:

- 10PCS Anascença Servo + 10PCS Shimpo REDUTOR

- 10Molo de liga PCS molde principal + 8PCS molde de curling

- Modelo: 150S all servo,

- Velocidade: até 150 PCs/min (9000 Copas/hora),

- Tamanho do copo: 3~ 16oz,

- Principal: 45~ 100 mm,

- Fundo: 38~ 70 mm,

- Altura: 45~ 135 mm,

- Material: 150~ 320 GSM 1PE & 2No papel,

- Peso: 3350KG,

- Máquina:3200x1650x1900mm,

- Coletor: 1100 x 1100 x 2100mm (contra o tamanho do copo ),

- Poder de trabalho 10kW, Poder total: 35KW,

- Poder: 380V 3-fase 50/60 Hz,

- Precisa de ar (pressão:0.3~ 0,5mpa, Saída:300~ 500 l/m),

- Aplicativo: quente (chá de café) frio (Cola JUIC Icecream) Copo de papel,

Máquina servo de produção de copo de papel com spray de água automático 150s

Máquina servo de produção de copo de papel com spray de água automático 150s

Máquina de copo de papel servo

Máquina de copo de papel servo