Info & Video of Handle paper cup making machine 100s

Watch Handle paper cup making machine 100s operation demo video

More vidoe list on youtube: https://www.youtube.com/@Feenot/featured

New tech Handle paper cup making machine 100s speed is 100 pcs/min, make 4~12oz hot coffee tea handle paper cups, two ultrasoic sealing, 10 divide open cam, stable & reliable, hot sale.

Firstly this machine improved on hot sale model 100s OC12, which speed is 100pcs/minute,

Handle paper cups are required by some customer who want to use handle hold hot water tea coffee cup, prevent hand hurt by the hot water.

While design this machine, research the market, most of the paper cup handle machine speed is around 50, 70 pcs per minute, we choose the stable model 100s cup machine, improved the speed to 100pcs per minute.

100s paper cup handle stick machine, one ultrasonic, one whole system of handle punch, separately cam control the handle sealing, and handle auto punch.

The functions as following: feed paper cup fan blank, feed roll paper for cup bottom, feed roll paper for cup handle, suck cup fan, punch cup handle disc, sealing handle with cup fan by ultrasonic, then cup wall sealing by ultrasonic, lift cup wall to main mold, bottom punch and insert, heating, knurling, cup top curling, discharge, count & pack.

While connect to the paper cup paking machine, make it full automatic, one packing machine online with 4, 6, paper cup bowl container machines.

Application: hot drinks tea coffee handle paper cups.

Handle paper cup making machine 100s specification

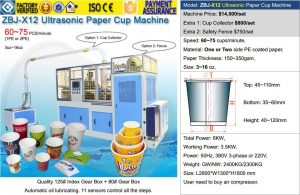

- Model: 100S HC12,

- Cup size: 4~12 oz,

- Top: 45~100 mm,

- Bottom: 30~72 mm,

- Height: 30~115 mm,

- Material: 150~320 gsm 1PE & 2PE paper,

- Weight: 2600KG,

- Machine: 2450x1350x1900mm,

- Collector: 900 x 700 x 2100mm,

- Total power: 13KW (ceramic hot air),

- Power: 380V 3-Phase 50/60 Hz,

- 10pcs main mold (steel + aluminium alloy),

- 25mm Thick Whole steel board structure base,

- PLC, intelligent control, automatic oil system,

- Handle welding: Ultrasonic,

- Cup wall welding: Ultrasonic,

- Cup bottom heating: Ceramic hot air (2pcs 4.4KW),

- Need Air (pressure:0.3~0.5Mpa, Output:300~500 L/m),

Paper cup making machine

Paper cup making machine