Self Water Spray Servo Pappbecher Making & Verpackungsmaschine, Einwegbecher machen, beschleunigen zu 150 PCs/min,

Voller Servo gefahren, mit Selbstwasserspray -System, intelligent, vollautomatisch, hohe Qualität, stabiler und zuverlässiger, weniger Wartungskosten.

Selbstwasserspray -System, Arbeitskräfteintensität reduzieren, Sparen Sie die Arbeitskosten,

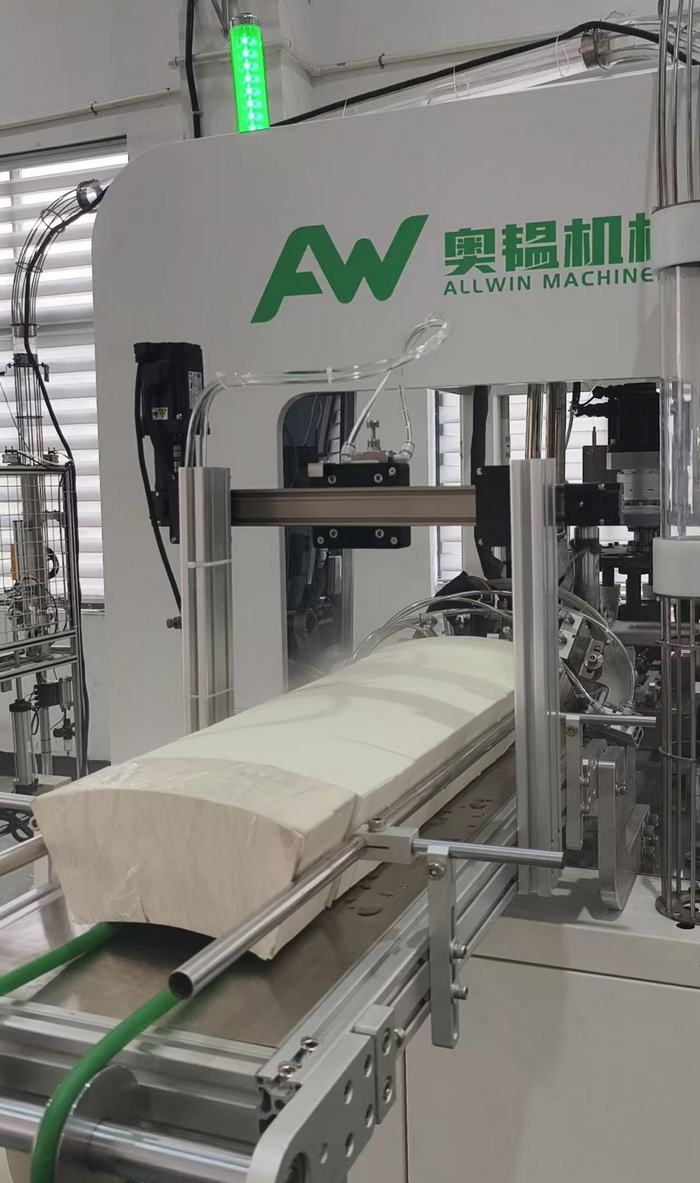

Tassenverpackungsmaschine, Automatische Verpackungspapierbecher in Plastiktüte, Papiertüte, Kosten sparen.

Self Water Spray Servo Pappbecher Making & Verpackungsmaschine

150S VOLLSTÄNDIGER PAPPUCK MACHE MOVERTE JEDER bewegende Teil durch einen Servomotor, um die Form zu erkennen, Locken, Bodenstanz und andere Prozesse von Pappbechern.

Die hohe Präzisionskontrolle des Servomotors macht den Produktionsprozess von Pappbechern stabiler und präziser.

Während sich die Verbindung mit Cup Packing Machine online verbinden, vollautomatisch, und sparen Laber -Kosten.

Anwendung: Heiße Getränke Kaffee Tee Milk Papierbecher, kaltes Getränk Coca Cola -Saftpapierbecher, Eispapierbecher, Pommes Chips Tassen, und andere Lebensmittelpaketlösung.

Im Vergleich zum alten sperrigen Komplex -Tassen -Making -Gerät (lange Achse, Getriebe, Cams, Ketten, Links).

Wenn alle Teile gebrochen werden, Der Benutzer sollte die gesamte Strukturausrüstung bewegen, schwer zu reparieren oder zu ersetzen, somit Maschinenstopp verursachen.

Papy Cup Machine Full Servo 150s Hauptmerkmale:

# 11Sets Anaskenz Servo + 11Sets Shimpo Reduzierer

# 10PCs Legierung Hauptform + 8PCs Lockenschimmel

1, Hohe Präzision: Der Servomotor kann eine genaue Positionsregelung und Geschwindigkeitskontrolle erreichen, Dadurch sicherstellen.

2, Hohe Effizienz: Die schnelle Reaktion und hohe Geschwindigkeit des Servomotors verbessern die Produktionseffizienz von Pappbechern erheblich.

3, Hoher Automatisierungsgrad: Ausgestattet mit fortschrittlichen Steuerungssystemen, Dies kann eine vollständig automatisierte Produktion von Papierfütterung bis zur Bildung von Pappbechern erzielen.

4, Beste Stabilität: Der Servomotor hat eine hohe Stabilität und Zuverlässigkeit, Dies kann die Ausfallrate und die Wartungskosten der Ausrüstung senken.

5, Maschine nimmt ein modulares Design an, um die Effizienz zu verbessern, Erleichterung der Wartung und Aufrüstung, und fördern Sie die Standardisierung und Kompatibilität;

6, Das gruppierte Servo -Bewegungssteuerungssystem sorgt für die Genauigkeit, Geschwindigkeit und Stabilität des Maschinenbetriebs;

7, Intelligentes Schmiersystem für zentralisierte Ölversorgung spart die Kosten für den regelmäßigen Ölersatz, reduziert die Schwierigkeiten der Ölverschmutzung, und spart Energie und ist umweltfreundlich;

8, 10-Die Interaktion zwischen Mensch und Maschinenmaschinen macht die Maschine bequem und effizient zu bedienen, und kann mit einem Erkennungssystem ausgestattet werden.

Self Water Spray Servo Pappbecher Making & Verpackungsmaschinenvorteil:

- 10PCS -Qualitätsservomotor -System Ersetzen Sie die Getriebe für alte komplexe Mechanismus,

- Alter sperriger langer Schacht-Cam-Gear einfacher Abnutzung, gebrochen,

- 1, Schräg saugen Papierservo,

- 2, Tassen Wandwickel & Ultraschalldichtung Servo,

- 3, Fan-Blank & Tasse Wandtransfer Servo,

- 4, Tassen Wandflip -Servo,

- 5, Tasse Wandliftservo,

- 6, Bottom Roll Feed Servo,

- 7, Bottom Disc drücken Servo nach oben,

- 8, Quietschendes Servo (unterer Schlag, Heizung, Knurling, Top Curling),

- 9, 10 Index Hauptformplatte Servo,

- 10, 8 Index Curling Formplatte Servo.

- Servo+ECAM+Plc+HMI, effizient, intelligent, stabil, zuverlässig,

- Voller Servo, Genauigkeit, stabil, zuverlässig, Einfacher Betrieb, weniger & Einfache Wartung.

- 10PCs Quality Verbündete Tasse Form, Winkel 36 Grad,

- 8PCs Lockenschimmel (zweimal zusammenrundend), Winkel 45 Grad,

- 38mm dicke Ganzstahlplattenstrukturbasis, stabil & zuverlässig,

- Lüfterwand Blankefutter 1 Meter (hohe Geschwindigkeit, Füttern Sie einmal mehr Rohlinge)

- Top Felge zweimal abgerundet, Tasse starker und bester Ausblick,

- Tassenwandschweißen: Ultraschall + Keramische heiße Luft,

- Bodenheizung: Keramische heiße Luft (2PCS 4.4KW),

Spezifikation der Pappbechermaschine Full Servo 150s:

- Modell: 150S Full-Service,

- Geschwindigkeit: 150 PCs/min (9000 Tassen/Stunde),

- Tassengröße: 3~ 16oz,

- Spitze: 45~ 100 mm,

- Unten: 38~ 70 mm,

- Höhe: 45~ 135 mm,

- Material: 150~ 320 GSM 1PE & 2Auf Papier,

- Gewicht: 3350Kg,

- Maschine:3200x1650x1900 mm,

- Kollektor: 1100 X 1100 x 2100 mm (gegen die Bechergröße ),

- Arbeitskraft 10 kW, Gesamtleistung: 35KW,

- Leistung: 380V 3-Phasen 50/60 Hz,

- Brauche Luft (Druck:0.3~ 0,5 MPa, Ausgabe:300~ 500 l/m),

- Anwendung: heiß (Kaffeee) kalt (Cola Safteis) Pappbecher,

Self Water Spray Servo Pappbecher Making & Verpackungsmaschine

Self Water Spray Servo Pappbecher Making & Verpackungsmaschine

Servo -Pappbechermaschine

Servo -Pappbechermaschine