Come realizzare bicchieri di carta ondulati e a doppia parete? Linea di macchine per la produzione di bicchieri di carta ondulati a doppia parete 150S, per produrre due strati antiscottatura, hot insulation coffee ripple double wall paper cups.

Require, single wall paper cup forming machine + double wall paper cup sleeve glue machine.

Come realizzare bicchieri di carta ondulati a doppia parete?

Come realizzare bicchieri di carta ondulati a doppia parete?

Per produrre bicchieri di carta ondulati a doppia parete, require machines working together,

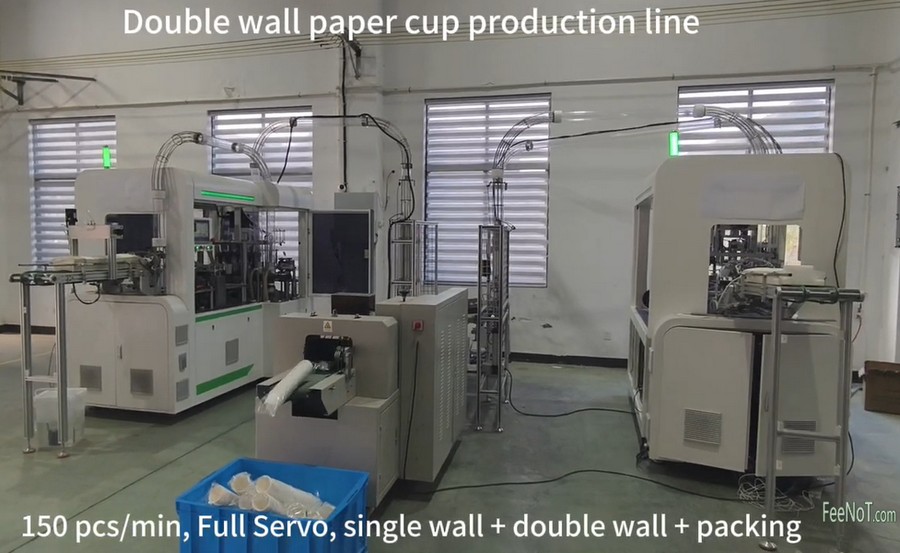

150È tutta una macchina per bicchieri di carta a parete singola servo + 150S DW16 macchina per maniche di tazze di carta a doppia parete tutta servo + macchina imballatrice

150È tutta una macchina per bicchieri di carta a parete singola servo + 150S DW16 macchina per maniche di tazze di carta a doppia parete tutta servo + macchina imballatrice

- 1st, 150Macchina per bicchieri di carta S servo, produrre bicchieri di carta a parete singola, tutto servocomandato, 150 pz/minuto.

- 2nd, Aggiungi un sistema di trasferimento intermedio, raccogliere e trasferire i bicchieri di carta a parete singola nella macchina per maniche a doppia parete,

- 3rd, macchina per bicchieri di carta a doppia parete ondulata , sigillare la manica del 2° strato, e avvolgere la manica/giacca attorno alle coppe a parete singola, tutto servocomandato, 150 pz/minuto.

- 4th, macchina da imballaggio di carta, produrre una borsa a 3 lati, confezionare bicchieri di carta in plastica / sacchetti di carta.

- Tutta la linea, Completamente automatico, ad alta velocità, stabile, intelligente.

Info of double wall paper cup production machine

Completamente automatico, tutto servo, Macchina per bicchieri di carta a doppia parete usa e getta da 8 once, produrre una tazza di carta da parati ondulata, bicchieri di carta a doppia parete rispetto alle dimensioni del cliente.

Mentre l'acqua calda, il caffè e il tè vengono versati in bicchieri di carta a parete singola, troppo caldo per tenerlo in mano, il calore scotterà il dito della mano, all'antiscottatura, creare un secondo muro attorno ai bicchieri di carta per farli raffreddare.

Stile a doppia parete: Manica cava: bicchieri di carta a doppia parete,

Manica diretta: bicchieri di carta ondulata/ondulata, bicchieri di carta goffrata, e così via.

Specification of double wall paper cup production machine

- Modello: 150S DW16,

- Velocità: fino a 150 pz/minuto,

- Taglie di tazza: 4~ 16oz,

- Superiore: 45~ 100 mm,

- Metter il fondo a: 30~72 mm,

- Altezza: 30~ 135 mm,

- Materiale: 150~ Carta patinata con pellicola da 320 g/m², carta con stampa lucida/verniciata,

- La colla ad acqua attacca il manicotto a doppia parete e la tazza interna.

- Colla ad acqua: (emulsione di acetato di polivinile),

- Opzione: Colla a caldo per la sigillatura delle pareti laterali, e così via.

- Peso: 3000KG,

- Macchina:3200x1650x2100 mm,

- Collettore: 900 X 700 X 2100mm (contro la taglia di coppa )

- Potenza totale: 30KW (potenza di lavoro 8KW),

- Energia: 380V 3-Fase 50/60 Hz,

- Hai bisogno di aria (pressione:0.3~ 0,5MPA, Produzione:300~ 500 l/m),

- Applicazione: Contenitore per bicchieri di carta a doppia parete ondulato,

Immagine:

Linea di macchine per la produzione di bicchieri di carta ondulati a doppia parete 150S

Linea di macchine per la produzione di bicchieri di carta ondulati a doppia parete 150S

Servo Paper Cupt Machine

Servo Paper Cupt Machine