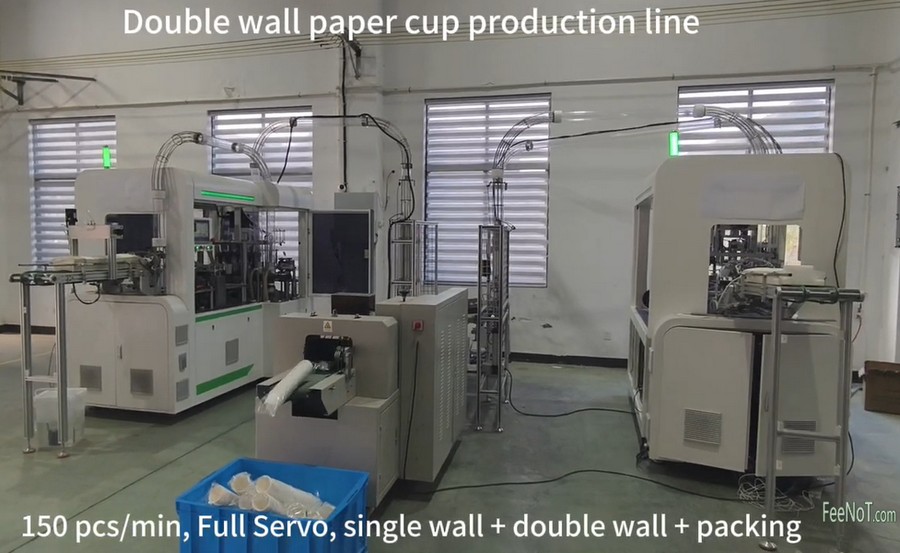

150S 모든 서보 커피 리플 이중 벽 종이컵 기계, 생산 속도는 최대 150 PC/분, 내부 단일 벽 종이컵에 재킷 슬리브를 만들고 감싸십시오., 2겹 종이컵 생산, 화상 방지 커피 컵, 보온 종이컵.

150S 모든 서보 커피 리플 이중 벽 종이컵 기계 정보:

첫 번째, 이중벽 리플 컵 기계는 자동 기계입니다, 아래와 같이 전체 프로세스를 실행한 후:

- 소매 팬 피드 및 빨아,

- 핫멜트 접착제 스프레이 (옵션),

- 초음파 밀봉 (구리 옵션 ),

- 벽을 주 금형으로 들어 올리십시오., 아래쪽 접기, knurling (중공 이중 벽 컵 슬리브),

- 슬리브 벽을 스틱 플레이트로 옮깁니다.,

- 원형 물 접착제를 뿌리세요 (서보 모터 제어, 원을 회전하다) 소매벽 안쪽,

- 컵을 소매까지 빨아들인다,

- 슬리브를 컵 테두리 공간으로 밀어 넣습니다.,

- 해고하다, 세고 수집하십시오.

뜨거운 물 커피 차를 벽 종이 컵에 넣으면서, 손으로 잡기에는 너무 뜨거워요, 더위가 손 손가락을 데게 할 것이다, 화상방지에, 종이컵 주변에 두 번째 벽을 만들어 뜨겁게 만들어 보세요..

시장에서, 이중 벽 스타일: 빈 종이컵 소매 기계, 잔물결 종이컵 소매 기계, 양각 종이컵 재킷 기계,

리플 이중벽 종이컵 만드는 방법?

- 리플 이중벽 종이컵을 생산하려면, 두 대의 기계가 함께 작동해야 함,

- 첫 번째는 단일 벽 종이컵 생산 기계입니다., 150S 서보 종이컵 기계.

- 중간 전송 시스템을 사용하세요, 단일 벽 종이컵을 이중벽 기계로 옮깁니다.,

- 두 번째는 이중 벽 컵 재킷 슬리브 랩 기계입니다., 리플 이중벽 종이컵 기계.

150S 모든 서보 커피 리플 이중 벽 종이컵 기계 사양

- 모델: 150S DW16,

- 속도: 최대 150 PC/분,

- 컵 크기: 4~ 16oz,

- 맨 위: 45~ 100 mm,

- 맨 아래: 30~72mm,

- 키: 30~ 135 mm,

- 재료: 150~320gsm 필름 코팅지, 광택/광택 인쇄 용지,

- 물 접착제는 이중벽 슬리브와 내부 컵을 붙입니다..

- 물 접착제: (폴리비닐 아세테이트 에멀젼),

- 옵션: 측벽 밀봉용 핫멜트 접착제, 등.

- 무게: 3000kg,

- 기계:3200x1650x2100mm,

- 수집기: 900 엑스 700 x 2100mm (컵 크기에 대해 )

- 총 전력: 30KW (작동 전력 8KW),

- 힘: 380v 3 상 50/60 HZ,

- 공기가 필요합니다 (압력:0.3~ 0.5mpa, 산출:300~ 500 l/m),

- 애플리케이션: 리플 이중 벽 종이컵 그릇 컨테이너,

장점 목록:

- 최신, 최첨단, 서보 드라이브 시스템,

- 특징: 인체 공학 개선, 효율성 증가, 안정성과 신뢰성을 보장했습니다.

- 전적으로 서보 중심입니다, 서보 모터는 모든 프로세스를 개별적으로 구동합니다..

- 서보 드라이브는 놀라운 정확도로 각 스테이션을 제어하기 위해 독립적으로 작동하고 동기화 된 모션을 조정하기 위해 함께 협력합니다..

- 서보 모터 시스템은 기존의 복잡한 메커니즘 변속기를 대체합니다.,

- 오래된 부피가 큰 긴 샤프트 캠 그어 쉬운 마모, 고장난,

- 서보+ECAM+PLC+HMI, 효율적인, 지능적인, 안정적인, 믿을 수 있는,

- 10PC 품질의 Ally Cup Mold, 각도 36 도,

- 8 인덱스 플레이트, 스틱 슬리브, 각도 45 도,

- 38MM 두꺼운 전체 철강 보드 구조 기반, 안정적인 & 믿을 수 있는,

- 슬리브 벽 블랭크 피더 1 미터 (고속, 한 번 더 빈 공간을 공급하십시오)

- 초음파를 이용한 슬리브 벽 용접 (+ 핫멜트 옵션),

그림:

150S 모든 서보 커피 리플 이중 벽 종이컵 기계

서보 페이퍼 컵 기계

서보 페이퍼 컵 기계