150S toate servo cafea ondulată mașină de pahar cu hârtie dublă, viteza de producție este de până la 150 PC -uri/min, faceți și înfășurați o mânecă de jachetă în jurul paharelor interioare de hârtie cu un singur perete, produceți pahare de hârtie cu două straturi, ceașcă de cafea antiopărire, pahare de hârtie termoizolantă.

150S toate informațiile despre mașina de pahare de hârtie cu perete dublu de ondulare a cafelei servo:

În primul rând, Mașina de cupe cu perete dublu este o mașină automată, după rularea unui întreg proces ca mai jos:

- Manșonul alimentat și aspirat,

- spray de adeziv topibil la cald (opţiune),

- etanșare cu ultrasunete (varianta cupru ),

- ridicați peretele la matrița principală, pliul de jos, moletă (manșon cu perete dublu gol),

- transferați peretele manșonului pe placa de lipire,

- pulverizați un clei de apă circular (comanda servomotoarelor, rotește un cerc) în interiorul peretelui mânecii,

- sorb până la mânecă,

- împingeți manșonul în spațiul marginii cupei,

- descărcare, numără și adună.

În timp ce apă fierbinte cafea ceai în pahare de hârtie de perete, prea fierbinte pentru a fi ținut de mână, căldura va opări degetul mâinii, la antiopărire, faceți un al doilea perete în jurul paharelor de hârtie pentru a fi fierbinte.

Din piata, stil perete dublu: mașină de mâneci pentru pahare de hârtie goală, mașină cu mâneci pentru pahare de hârtie ondulată, mașină de înveliș pentru pahare de hârtie,

cum să faci pahare de hârtie cu perete dublu ondulat?

- Pentru a produce pahare de hârtie cu perete dublu ondulat, necesită două mașini care lucrează împreună,

- primul este mașina de producție a paharelor de hârtie cu un singur perete, 150S servo mașină de pahare de hârtie.

- Utilizați un sistem de transfer intermediar, transferați paharele de hârtie cu un singur perete pe mașina cu perete dublu,

- iar al doilea este mașina de înfășurare a mânecilor cu perete dublu, mașină de pahare cu hârtie de perete dublu ondulat.

Specificația mașinii de pahare de hârtie cu perete dublu 150S toate servo de cafea ondulată

- Model: 150S DW16,

- Viteză: până la 150 PC -uri/minut,

- Dimensiunea cupei: 4~ 16oz,

- Top: 45~ 100 mm,

- Fund: 30~72 mm,

- Înălţime: 30~ 135 mm,

- Material: 150Hârtie acoperită cu film de ~320 g/m², hârtie cu imprimeu lucios/lac,

- Adezivul de apă lipește manșonul cu perete dublu și cupa interioară.

- Lipici de apă: (emulsie de acetat de polivinil),

- Opţiune: Adeziv termofuzibil pentru etanșarea pereților laterali, și așa mai departe.

- Greutate: 3000KG,

- Maşină:3200x1650x2100mm,

- Colector: 900 x 700 x 2100mm (împotriva mărimii cupei )

- Putere totală: 30Kw (putere de lucru 8KW),

- Putere: 380V 3-fază 50/60 Hz,

- Aveți nevoie de aer (presiune:0.3~ 0,5mpa, Ieșire:300~ 500 L/m),

- Aplicație: ripple perete dublu pahare bol recipient,

Lista de avantaje:

- Cel mai nou, de ultimă oră, sistem de servomotor,

- Caracteristici: ergonomie îmbunătățită, eficiențe crescute, stabilitate si fiabilitate asigurate.

- Este în întregime servo-acționat, servomotoarele conduce tot procesul separat.

- Servomotoarele funcționează independent pentru a controla fiecare stație cu o precizie remarcabilă și lucrează împreună pentru a coordona mișcarea sincronizată.

- Sistemul servomotor înlocuiește vechiul mecanism complex de transmisie,

- Vechi, voluminoase, arbore lung-cam-angrenaj ușor de uzat, spart,

- Servo+ECAM+PLC+HMI, eficient, inteligent, stabil, de încredere,

- 10mucegai cupa aliat de calitate buc, unghi 36 grad,

- 8 placa index, mâneca lipită, unghi 45 grad,

- 38mm Grosime Baza structurii din oțel întreg, stabil & de încredere,

- Alimentator cu manșon de perete 1 metru (de mare viteză, hrăniți mai multe semifabricate o dată)

- Sudarea peretelui manșonului prin ultrasunete (+ optiunea de topire la cald),

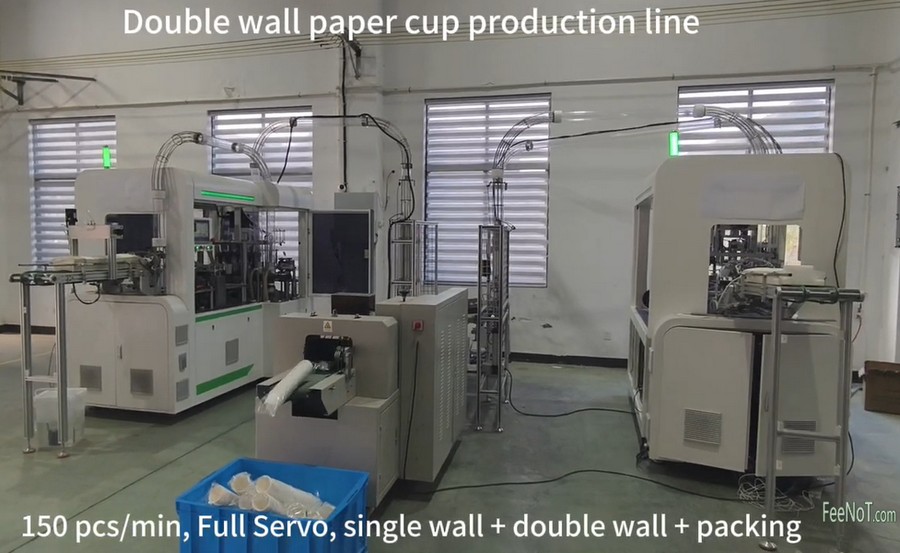

Imagine:

150S toate servo cafea ondulată mașină de pahar cu hârtie dublă

150S toate servo cafea ondulată mașină de pahar cu hârtie dublă

Mașină de hârtie servo

Mașină de hârtie servo