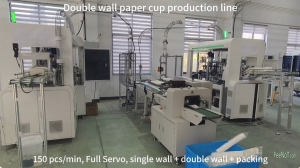

Mașină de pahare cu hârtie dublă – Confecţionarea jachetei cu mâneci ondulate, toate servoacționarea, un echipament complet automat de formare a containerelor de hârtie, faceți și înfășurați un al doilea strat de mânecă/jachetă în jurul paharelor interioare de hârtie cu un singur perete.

Viteza de producție este de până la 150 PC -uri/min, servomotor de cea mai bună calitate, stabil, viteză, inteligent.

Realizarea de pahare de hârtie cu perete dublu pentru cafea, ceai, termoizolare/antiopărire.

Double Wall Paper Cup Machine 150s – Confecţionarea jachetei cu mâneci ondulate

În timp ce apă fierbinte, ceaiul de cafea se umple în pahare de hârtie de perete, sunt prea fierbinți pentru a fi ținute cu mâna,

Pentru că căldura va opări degetul mâinii, la antiopărire, așa că ar trebui să facă un al doilea perete în jurul paharelor de hârtie pentru a fi fierbinte.

Mașină completă servo ondulată cu perete dublu pentru mâneci pentru pahare, produce un pahar de hârtie de perete, pahare cu perete dublu față de dimensiunea comenzii clientului.

Stil dublu perete: pahare goale de hârtie, pahare de hârtie ondulată/ ondulată, pahare de hârtie în relief.

Cum să faci pahare de hârtie cu perete dublu ondulat?

Pentru a produce pahare de hârtie cu perete dublu ondulat, necesită două mașini care lucrează împreună,

- 1Sf, 150S servo mașină de pahare de hârtie, produce pahare cu hârtie de perete unică, toate servo actionate, 150 PC -uri/minut.

- Adăugați un sistem de transfer intermediar, colectați și transferați pahare de hârtie cu un singur perete pe mașina cu manșon cu perete dublu,

- 2nd, mașină de pahare cu hârtie de perete dublu ondulat , sigilați manșonul al 2-lea strat, și înfășurați mâneca/jacheta în jurul unor cupe cu un singur perete, toate servo actionate, 150 PC -uri/minut.

- 3rd, Mașină de ambalare a cupei de hârtie, produce saci cu 3 laturi, ambalarea paharelor de hârtie în plastic / pungi de hârtie.

- Întreaga linie, Complet automat, de mare viteză, stabil, inteligent.

Specificația mașinii de pahare cu hârtie dublă 150S Full Servo

- Model: 150S DW16 Servo complet,

- Viteză: până la 150 PC -uri/minut,

- Dimensiunea cupei: 4~ 16oz,

- Top: 45~ 100 mm,

- Fund: 30~72 mm,

- Înălţime: 30~ 135 mm,

- Material: 150Hârtie acoperită cu film de ~320 g/m², hârtie cu imprimeu lucios/lac,

- Adezivul de apă lipește manșonul cu perete dublu și cupa interioară.

- Lipici de apă: (emulsie de acetat de polivinil),

- Opţiune: Adeziv termofuzibil pentru etanșarea pereților laterali, și așa mai departe.

- Greutate: 3000KG,

- Maşină:3200x1650x2100mm,

- Colector: 900 x 700 x 2100mm (împotriva mărimii cupei )

- Putere totală: 30Kw (putere de lucru 8KW),

- Putere: 380V 3-fază 50/60 Hz,

- Aveți nevoie de aer (presiune:0.3~ 0,5mpa, Ieșire:300~ 500 L/m),

- Aplicație: ripple perete dublu pahare bol recipient,

Procesul de producție al mașinii de pahare cu hârtie dublu Ripple:

- Introduceți manșonul cu perete dublu pe seenderul ventilatorului și intrarea,

- Aspirați automat ventilatorul manșonului, alimentare la mașină,

- Sigilați automat partea laterală a peretelui manșonului, Etanșare cu ultrasunete (varianta cupru ), (adăugați spray de adeziv termofuzibil, opţiune),

- Ridicați peretele manșonului la matrița principală, pliul de jos, moletă (manșon cu perete dublu gol),

- Aruncați și transferați peretele mânecii pe placa lipită,

- Pulverizați un clei circular de apă (comanda servomotoarelor, rotește un cerc) în interiorul peretelui mânecii,

- Servo alimentare cu un singur perete în peretele manșonului,

- Împingeți manșonul în spațiul pentru marginea cupei cu un singur perete,

- Descarcare, numără și adună.

Servoare

- Servo de hârtie de aspirat oblic,

- Servo sigilare cu ultrasunete,

- Servo clemă aripă perete cupă,

- Fan Cup & servo de transfer de perete,

- Servo flip perete cupa,

- Servo de ridicare a peretelui cupei,

- Servo moletat,

- 10 servo placa de divizare,

- 8 servo placa de divizare,

- Servo de descărcare a cupei,

- Servo pulverizare adeziv,

- Cupă servo separată,

Imagine:

mașină-pașină-pentru-perete-dublu-150S-2

Mașină de hârtie servo

Mașină de hârtie servo