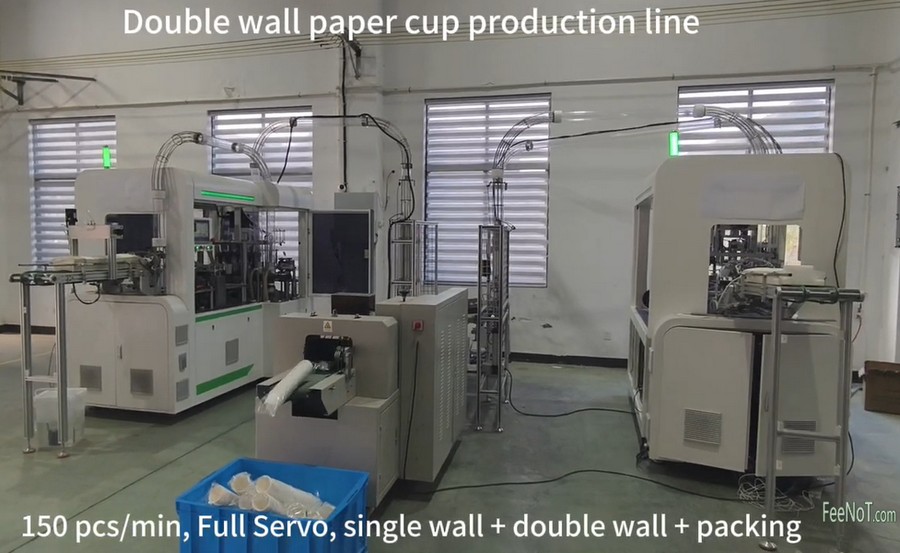

150S all servo coffee ripple double wall paper cup machine, production speed is up to 150 pcs/min, make and wrap a jacket sleeve around inner single wall paper cups, produce two layer paper cups, anti scalding coffee cup, hot insulation paper cups.

150S all servo coffee ripple double wall paper cup machine info:

Firstly, Double wall ripple cup machine is an automatic machine, after running a whole process as below:

- sleeve fan feed and suck,

- hot melt glue spray (option),

- ultrasonic sealing (copper option ),

- lift wall to main mold, bottom fold, knurling (hollow double wall cup sleeve),

- transfer sleeve wall to stick plate,

- spray a circle water glue (servo motor control, rotate a circle) inside the sleeve wall,

- suck cup down to sleeve,

- push the sleeve into cup rim space,

- discharge, count and collect.

While hot water coffee tea into single wall paper cups, too hot to hold by hand, the heat will scald the hand finger, to anti-scalding, make a second wall around paper cups to provent hot.

From the market, double wall style: hollow paper cup sleeve machine, ripple paper cup sleeve machine, emboss paper cup jacket machine,

how to make ripple double wall paper cups?

- To produce ripple double wall paper cups, require two machines working together,

- first is the single wall paper cup production machine, 150S servo paper cup machine.

- Use a mid-transfer system, transfer the single wall paper cups to double wall machine,

- and second is the double wall cup jacket sleeve wrap machine, ripple double wall paper cup machine.

Specification of 150S all servo coffee ripple double wall paper cup machine

- Model: 150S DW16,

- Speed: up to 150 pcs/minute,

- Cup size: 4~16oz,

- Top: 45~100 mm,

- Bottom: 30~72 mm,

- Height: 30~135 mm,

- Material: 150~320gsm film coated paper, paper with glossy/varnish print,

- Water glue stick the double wall sleeve and inner cup.

- Water Glue: (polyvinyl acetate emulsion),

- Option: Hot melt glue for side wall sealing, and so on.

- Weight: 3000KG,

- Machine:3200x1650x2100mm,

- Collector: 900 x 700 x 2100mm (against cup size )

- Total power: 30KW (working power 8KW),

- Power: 380V 3-Phase 50/60 Hz,

- Need Air (pressure:0.3~0.5Mpa, Output:300~500 L/m),

- Application: ripple double wall paper cups bowl container,

Advantage list:

- Newest, state of the art, servo drive system,

- Features: improved ergonomics, increased efficiencies, ensured stability and reliablity.

- It is entirely servo-driven, servo motors drives all the process separately.

- Servo drives work independently to control each station with remarkable accuracy and work together to coordinate the synchronized motion.

- Servo motor system replace old complex mechanism transmission,

- Old bulky long shaft-cam-gear easy wear out, broken,

- Servo+ECAM+PLC+HMI, efficient, intelligent, stable, reliable,

- 10pcs quality ally cup mold, angle 36 degree,

- 8 index plate, stick sleeve, angle 45 degree,

- 38mm Thick Whole steel board structure base, stable & reliable,

- Sleeve wall blank feeder 1 meter (high speed, feed more blanks one time)

- Sleeve wall welding by ultrasonic (+ hot melt option),

Picture:

150S all servo coffee ripple double wall paper cup machine

Servo paper cup machine

Servo paper cup machine